Understanding Thermal Print Head Life

21/11/18

The print head is a very delicate and important part of any thermal printer. Proper care must be taken with any portion of the printer, but it is especially important with this component. The goal of this document is to show you how to get the most mileage out of that critical component.

There are certain items on a thermal printer which are consumables. We traditionally think of consumables as a label or ribbon, but other wear items such as print heads and platens need to be considered as consumables as well.

The print head is an item which comes into constant contact with a moving product; this of course being the labels, ribbon and platen roller (the roller directly underneath the print head). The quality of the labels and ribbon, as well as the proper maintenance and care, will have a direct effect on the print heads life.

This is much like the tyres on your car, if you don’t periodically rotate, balance and align them you’ll end up replacing them much quicker compared to someone who does the manufacturers' recommended maintenance.

1. Cleaning of the print head.

It is recommended that you clean the print head and platen roller after every ribbon change for Thermal Transfer operation or after every media change for Direct Thermal operation. Make sure to only clean with either a SATO packaged cleaner or a non-abrasive, lint-free cloth and Isopropyl Alcohol (90% or higher). Doing this regularly is the easiest way to get the most mileage out of the print head.

Monitor how dirty the cloth is that you use to clean the print head with and adjust the length of time between cleanings. Certain materials and environments may contribute to the residue build up and more cleanings may be required, or in combination with SATO Print Head Cleaning sheet.

Make sure to never touch the print head with your bare hands. The oils or other contaminants on your hands can have a negative effect on print head life.

You may use a brush and/or compressed air to clean any dust fibres that are in the media path or inside the printer. A can of approved compressed air should only be used. You would never use the compressed air from air assist hose(s) or compressors, as there are typically water vapours or other distillates that can cause issues with the longevity and operation of these components. If using compressed air, care should be taken not to spray directly onto the print head as thermal properties could cause damage to the protective coating on the print head elements.

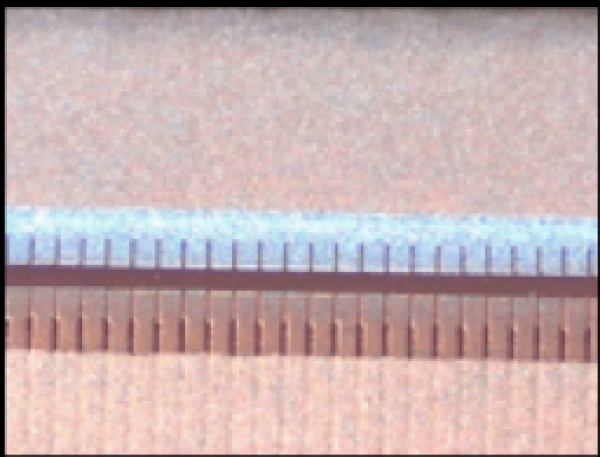

Print head properly maintained (see picture 1)

Print head not maintained properly (see picture 2)

In the examples above, both of these print heads have seen the same number of labels where one got regular cleanings and one did not. Both have since been cleaned and the results show one print head broken and the other which still works properly.

2. Choosing the right media.

As previously stated the print head is a wear item and will eventually fail. The big question is: when will it fail?

Not cleaning the print head leads to unwanted residue that builds upon the print head. Although the printer may still be printing, you will have to continue to increase the print head heat to get the same darkness and the quality will start to fade. With the increased heat and increased residue, there is more heat trapped at the print head. This residual heat will eventually cause the protective layer to crack and the print head will be damaged.

The amount of residue and how quickly it builds up will depend on the labels, ribbon and environment, your maintenance and the cleaning frequency.

There is a constant friction between the print head and the ribbon and/or labels. This friction will eventually wear the protective layer of the print head off. Once this protective layer is gone, the printing elements are exposed and will be damaged.

A couple of terms:

Direct Thermal: The use of heat sensitive label stock. When the proper amount of heat is transferred to a specific area, the label will change colours.

Thermal Transfer: The use of a ribbon and a label. The ribbon is then melted to the top layer of the labels.

Adhesive Ooze: The back of the label contains an adhesive which allows it to stick to the product that you’re labelling. If there is too much adhesive or the roll is wound too tight the adhesive bleeds to the surface around the edges of the label.

Perforation: A slotted cut usually at the top of the form to ensure easy label tear away from the printer after the label has been printed. This is normally done when a printer is away from the primary application of the labels to the product.

When using either method of printing, it is important that you chose a good quality product.

When Direct Thermal labels are being used it is especially important that care is taken in the quality of the labels as this is what comes into constant contact with the print head. If the face sheet is of poor quality, if there is excessive adhesive ooze, or if the perforation is cut towards the face of the stock, you will have premature print head failures.

When using Thermal Transfer, it is important to make sure that both the ribbon and labels are of good quality and matched appropriately. The back of the ribbon comes into constant contact with the print head, which if is of poor quality or has been exposed to environmental factors outside its specification can leave unwanted deposits on the print head.

It is always recommended that the ribbon be slightly bigger than the label stock so that the label is not exposed to the print head. If the ribbon is of good quality, it will protect the print head from the abrasiveness of the label stock.

The ribbon can also build up Electrostatic Discharge (ESD) which can destroy the components of the print head. Make sure to operate the printer with all original parts and ensure that the covers are closed while the printer is in operation.

3. Printer maintenance.

Although cleaning the printer and print head will greatly increase the print heads life, proper maintenance and setup will too.

Use only genuine SATO parts to guarantee warranty and proper printer functionality.

Print head replacement:

When the print head does fail it is important that a trained technician replaces it as improper print head alignment and balance can affect not only the print quality but also its life. Much like the tyre on your car, if it is misaligned, it will wear a grove in one area of the tyre while leaving the remainder intact; the same rule applies for our print heads. The problem with both scenarios is that you have an unusable part due to an uneven wear.

A misaligned print head will cause the need for more heat to transfer the image to the paper. The more heat applied to the print head, the higher the chance of premature failure. If this has been adjusted at factory settings during the course of the previous head’s installation, it is recommended that it be realigned with the new one.

Use only enough heat necessary to transfer a quality image to the label. There is no need for excessive heat as more heat can affect the life of the print head.

When maintaining the printer, be sure to take into account ESD. ESD can cause component failure, which of course, includes the print head. Make sure that you’re properly grounded any time you replace a part.

Platen roller replacement:

Over time, the platen roller will exhibit wear from the media thickness and pressure being exerted from the print head assembly. When the platen roller exhibits wear, most times other adjustments are made to compensate for the circumference of the platen roller with treading effects of operation, thus increasing friction/wear and tear on the print head. The platen roller is warranted for 30km, but it should be inspected regularly to ensure proper diameter is across the shaft. If you can see visible deviation on the platen roller, it needs to be replaced and proper adjustments for both alignment and the print head pressure need to be performed so it is equal across the entire print area, not just for the width of media.

4. Environment.

The environment can have an adverse effect on the printer as well as the labels.

If the printer is used outside the printer’s specifications, it may have an adverse effect on the life of the print head. If there is possible exposure to water, excessive heat or cold, you may need to consider an enclosure for the printer.

If the labels and ribbon are stored in an environment outside of their storage specification you can damage the labels and ribbon. This can cause unwanted changes to the properties of the label and ribbon, which can, in turn, cause unwanted reactions to the print head and/or leave unwanted residue that would not normally contaminate the printer if stored correctly.

5. Contacts and where to buy.

You can purchase quality labels and ribbons by contacting us:

Link to the enquiry form

Or by calling us at - GMC phone number.

More information on our Service Contracts page